- Altering its course, Toyota announces heavy investments in EV production, including three new batteries and entirely reworked production lines.

- Solid-state batteries as well as NCM Monopolar technology with a claimed 621 miles of range make up the future of Toyota’s BEVs.

- In the footsteps of Tesla, Toyota will employ giga casting as well as autonomous production lines overseas, while the company simultaneously builds a North American battery research facility in Michigan.

Toyota hasn’t exactly jumped on the electric vehicle bandwagon. With one dedicated EV crossover on the market and a few new hybrid models, it’s loosely keeping up with broad industry standards while remaining wedded to the hybrid sector it pioneered. In fact, the brand lost its former CEO and public EV skeptic, Akio Toyoda, earlier this year in a corporate restructuring focused on electrification, replacing Toyoda with former Lexus branding officer Koji Sato.

The months since Sato’s appointment have been markedly different, as Toyota softens its EV stance and even hints at an impending new electric architecture. But Toyota is taking it one step further this week, confirming an overhaul of its electric-vehicle production and parts processes.

Unveiling a sort of technology roadmap, Toyota confirms it will launch a more durable, energy-dense nickel cobalt manganese lithium-ion battery by 2026, with 621 miles of range and a fast charge time of 20 minutes. These bZ4x-adjacent NCM batteries will be reserved for performance vehicles or high-end luxury models, though Toyota has a plan for its lower-end units as well.

Using the bipolar structure battery (found in the Japanese-market Aqua and Crown hybrid vehicles), Toyota will expand this LFP technology to new BEV models, with the company claiming a 20% increase in cruising range and a 40% reduction in cost compared to the current bZ4x.

EV enthusiasts can also expect a high-performance version of Ni series Bipolar lithium-ion batteries, indicating the possibility of low-cost, high-performance EVs to come from Toyota. These batteries will feature a high-nickel cathode, increasing range by 10% while lowering costs 10%, and are set for practical use by 2028.

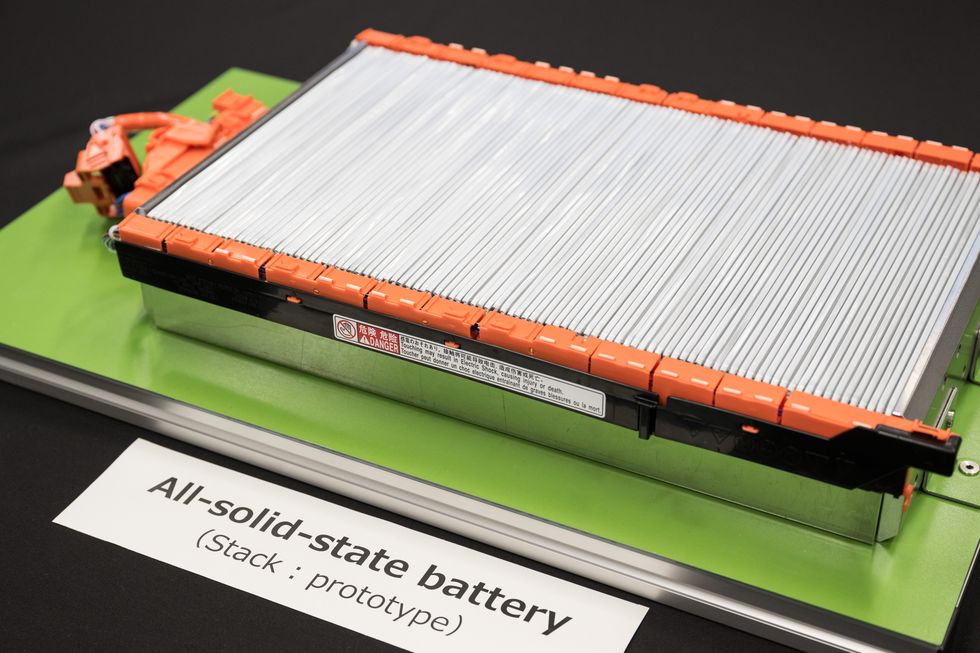

Such advancements are already in the works, Toyota says, but innovating beyond the near future is essential, company executives said. And Toyota sees solid-state batteries as undoubtedly the way forward, according to its EV blueprint. The company is accelerating its development of solid-state batteries in large part due to “a technological breakthrough that overcomes the longstanding challenge of battery durability,” but also because it estimates range expanding some 20% with solid-state batteries.

All of these percentages are hard to quantify when they’re stacked on top of each other and the company provides examples of improvements without any hard numbers. Even so, it signals that Toyota is well aware of how quickly it needs to expand its EV reach.

In order to do so, Toyota will need to re-develop and expand its production facilities, from a chassis and battery standpoint. Citing increased profitability, the company plans to use giga-casting technology (high-pressure aluminum die-casting machines) for its future EV platforms, reducing the sheer amount of sheetmetal parts. This production approach has certainly worked for Tesla, despite early-model production quality issues.

Toyota says it is ruling out the conveyor style of production for its future EV chassis, instead relying on a self-propelling assembly line. This approach will largely automate the process, allowing mass-produced models to move from process to process independently and creating more model flexibility at each plant. Notably, Toyota says this approach will significantly reduce the workers needed for production.

In tandem with this week’s news, Toyota also says it is developing a new battery research facility in Michigan. Investing $50 million, the Japanese brand will construct a North American R&D headquarters in York Township near Ann Arbor, specifically focusing on battery evaluation.

Given the current state of Inflation Reduction Act tax credit provisions, establishing manufacturing roots in North America (a battery plant in North Carolina and three-row electric SUV assembly in Kentucky) is a no-brainer. But Toyota says the R&D facility is also intended to help serve North American consumers better.

Driving needs and charging habits vary greatly even from state to state, but the American approach to electric vehicles has, thus far, been focused on a balance of long-range and high performance. For Toyota, understanding these nuances will be essential to producing a competitive product. And the ability to analyze US charging infrastructure firsthand will play a large part in the company’s regional development process, the release explains.

Toyota’s approach to EVs is shifting quickly but remnants of the previous corporate culture remain, as Toyota dedicated a significant portion of its presentation to hydrogen and e-fuels. While its approach to fuel-cell electric vehicles and hydrogen primarily hinges on commercial vehicles, Toyota is joining the likes of European manufacturers such as Porsche in exploring carbon-neutral biofuels.

Trialing hydrogen, synthetic fuels, and bioethanol fuels from renewable energy sources, Toyota says certain countries or regions where electricity demands are challenging, such as Brazil or India, would be prime for e-fuel technology.

Ultimately, echoing the company’s long-held talking point, the future-looking report says Toyota wants to deploy the right vehicle in the right place at the right time. For a brand that has been the world’s top-selling automaker for three straight years, this isn’t surprising, but Toyota will need more than improved production and better batteries to sell EVs. Especially in the US, the balance needed will be between affordable costs and inherent excitement.

If you’re an EV skeptic, what would convince you to buy an EV? Please share your thoughts below.

Associate Editor

A New York transplant hailing from the Pacific Northwest, Emmet White has a passion for anything that goes: cars, bicycles, planes, and motorcycles. After learning to ride at 17, Emmet worked in the motorcycle industry before joining Autoweek in 2022. The woes of alternate side parking have kept his fleet moderate, with a 2014 Volkswagen Jetta GLI and a 2003 Honda Nighthawk 750 street parked in his South Brooklyn community.

Read the full article here