Fredrika Klarén isn’t a huge fan of Hamburg, Germany.

Her personal climate constitution affords one international flight a year, so most of her travel from her home in Gothenburg, Sweden, is by train. Hamburg is the hub where she often misses a connection to Brussels or London or Paris or any number of places across the continent.

Klarén, however, is head of sustainability at Polestar, a Gothenburg-based electric vehicle maker; she has to walk the climate walk, no matter how irksome and inconvenient.

“I don’t know what it is, but I find myself literally nauseous when I fill up a petrol car,” she explains.

Klarén’s corporate rivals aren’t nearly as austere, and they’ve spent the past few months pumping the brakes on electric car production. She cashed in last year’s flight zipping to United Nations climate talks in Dubai, and only noticed two other car companies at the summit.

“I’m starting to see a trend where they aren’t coming to the table,” she says. “I mean, an industry that stands for 15% of the world’s greenhouse gas emissions doesn’t even show up? Come on!”

To be fair, among the world’s 14 million or so autoworkers, Klarén is an anomaly. The industry has people tracking the cost and quality of each widget. Carbon, however, has only recently entered the equation.

In the U.S. alone, there are 283 million cars, trucks and buses. Transportation accounts for nearly 30% of the country’s greenhouse gas emissions, according to the Environmental Protection Agency. Manufacturing, maintenance and the hardware needed to break vehicles down when they’re done being useful can add even more emissions.

Polestar saw these figures as an opportunity to do more than just make EVs. When it was spun out of Volvo in 2017, it made sustainability its North Star — a brand guidepost akin to “luxury” at Mercedes Benz or “performance” at Ferrari. No other car company has been as thorough and transparent in measuring how dirty its operations are and working to clean them.

Make no mistake, that’s both a climate strategy and a corporate strategy. Someone torn, for example, between a Polestar and a Ford may notice that the latter doesn’t put a carbon figure on its cars. If that person cares about the climate, they may see Polestar’s bright, “green” blinker and become a customer.

“It doesn’t sell cars in that primitive, direct translation,” Polestar Chief Executive Officer Thomas Ingenlath says of the strident sustainability. “But for our brand to be that serious, transparent and authentic … is absolutely important.”

Carbon hunter

Klarén is the tip of that spear; accounting for every ounce of emissions embodied in Polestar cars, from the diesel-burning backhoes at the lithium mine to the junkyard machinery that will eventually tear vehicles apart once they’ve reached the end of their life.

She’s a carbon hunter in her own company, looking for cuts in every nook and cranny of Polestar’s vast global supply chain. That’s arguably the easy part. The larger challenge: forcing the rest of the auto industry to do the same.

There’s some evidence that she’s making progress on that front. In recent months, a wave of startups have begun publishing reports detailing the carbon footprints of their cars, including Fisker and Rivian. Larger, more established rivals such as Hyundai and BMW are dabbling in public carbon accounting as well.

“Honestly, I sometimes have to pinch myself because we have such an opportunity here,” Klarén says. “Eventually, everyone will have to do this.”

A car is basically a cloud of carbon dioxide on wheels. For gas-burning cars, most of the carbon is emitted with each mile it’s driven. For EVs, the majority of those emissions are tied to making the machine itself.

Electric models are far cleaner over time, but they don’t cross the carbon rubicon until they’ve been on the road awhile. In the U.S., it takes a little more than two years — about 25,000 miles (40,000 kilometers) of driving — to reach that threshold, according to recent BloombergNEF research.

Klarén is trying to speed up the timeline for Polestar’s carbon superiority from the start. Perhaps her greatest accomplishment came last November when a factory in Chengdu, China, started stamping out the brand’s fourth vehicle, known simply as “4.”

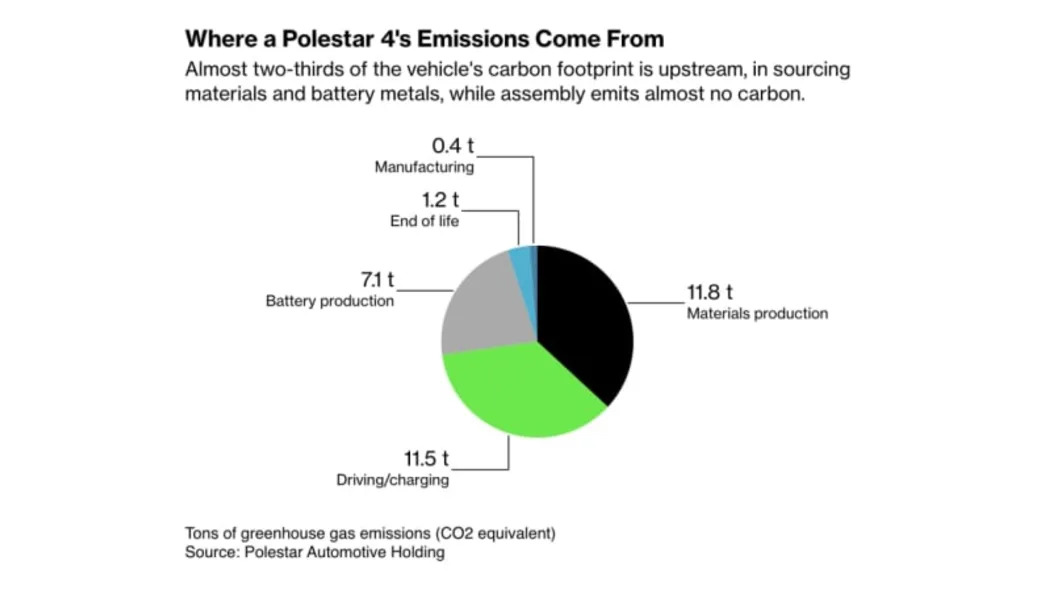

Polestar says that from the rubber plantation to the wrecker, the base model of the little ride will be responsible for 32 tons of CO2-equivalent emissions based on the global energy mix. That’s still a major chunk of pollution, roughly equivalent to charging 2.1 million iPhones, grilling 1,500 propane tanks worth of burgers or powering 4 US homes for a year.

Compare that to the Volvo XC40, though, and the number becomes much more impressive. (Polestar was spun out of Volvo, so the two models are corporate siblings.) Making, fueling and driving an XC40 to its grave requires about 58 tons of carbon, according to the Massachusetts Institute of Technology.

Jessika Trancik, an MIT professor, built the school’s CarbonCounter because consumers weren’t getting this kind of data from the carmakers directly. Her goal was to connect the dots for people shopping for a sedan or SUV and influence their choice.

“Think about building a power plant, those decisions are made by large entities,” she explains. “But a car is essentially a tiny power plant, and consumers have quite a bit of choice when it comes to their cars.”

How much they factor in sustainability remains to be seen, though, especially as some automakers slash EV prices or introduce cheaper models altogether. Piper Sandler & Co. only expects Polestar to deliver 84,000 cars this year and recently cut its price target on the company’s shares from $3 to $2.

“We’re growing concerned industry-wide EV price cuts may prompt consumers to ‘shop around’ for cheaper offerings,” analyst Alexander Potter wrote in a March 14 note.

‘A rabbit warren’

Finding exact, easily accessible carbon comparisons also remains difficult, making it hard for would-be buyers to even factor it into their decision. The Polestar 4 may well be one of the least carbon-intensive cars ever made. “May” because while car companies are increasingly interested in carbon accounting — product-level breakdowns known as “life-cycle assessments” or LCAs — they typically don’t publish their results.

As technical director at Sphera, an ESG consultancy, Christoph Koffler advises scads of car executives on carbon accounting. He estimates that 80% of life-cycle emissions data never sees the light of day.

Even with the best intentions, the numbers are extremely hard to come by. A contemporary vehicle requires around 1,400 different suppliers for things such as seat belts and brake pads. Including companies that provide core materials — so-called Tier 2 suppliers, such as the folks making the seat belt fabric — balloons that number further.

“When you get down to the level of the mining,” Koffler explains, “it can be a bit of a rabbit warren.”

In Klarén’s incessant hunt to cancel carbon, no detail is too small. The floor mats of the Polestar 4 are woven from old fishing nets. The door panels are made out of natural fiber and polypropylene, which can be recycled together. The seat upholstery is recycled polyester, a material Polestar cooked up with help from the Swedish School of Textiles, and it’s knitted to reduce waste.

For changes in production, Klarén has to talk to Geely and/or Volvo, which run the plants that manufacture Polestar vehicles. To cut carbon further up the supply chain, such as metals or materials, she has to talk to the companies making the components.

“You have to be a bit creative,” she explains.

‘A change of mind’

Beatrice Simonsson, Polestar’s head of product management, was used to worrying about time, technique and cost; when Klarén was hired in 2020, she added sustainability to that list.

“Instead of having it as an add-on — like an accessory — sustainability had to be integrated into each and every decision,” she recalls. “It’s a little bit of a change of mind.”

Klarén’s role is almost always at odds with others in the company. Success for her often adds cost and complexity, to say nothing of extra work. That means in addition to being a carbon hunter, she also has to be a diplomat.

Reflecting those dual roles, Klarén has built a reputation for being both uncompromising and pragmatic. “I think we complement each other,” Simonsson says. “We nag a little bit, but we need to nag a little bit; otherwise we don’t move forward.”

Often, Klarén has to back down because the carbon cuts aren’t worth the higher costs. “What we’re going for now are things we can switch to quite easily,” she says. “As we progress, the fruits are going to hang higher and higher.”

Still, most of the carbon that goes into an EV comes from just a few places, namely, the metal and the battery materials.

One of Klaren’s biggest wins came from aluminum, a metal that requires a tremendous amount of energy to produce owing to the high heat and electricity needed to smelt it.

Klaren hunted down aluminum smelters hooked up to zero-carbon hydropower plants in China’s Yunnan province, then leaned on parts makers, convincing them to switch their suppliers to get cleaner metal. In part because of the smelter switch, Polestar was able to cut about 4 tons of emissions — roughly 8% of the total emissions — from materials production per car from the time between its second model and its fourth. The change also incidentally lowered costs, creating a true win-win.

“You really have to motivate the change,” she says, “and make them understand this is something that will benefit them, too.”

‘The power of collective action’

Paradoxically, Klarén comes from a carless place — a small island near Gothenburg called Donsö. The population of just 1,500 gets around by boat and bike. For Klarén, it was an idyllic childhood steeped in saltwater and snowy winters.

“You knew everyone raised each others’ kids and you had to work together — you had no choice,” she recalls. “It really instilled the importance of community and the power of collective action.”

Much of Klarén’s resiliency came from a car crash. In 1986, an accident paralyzed her father, a ship captain who mainly piloted oil tankers.

From his wheelchair, he figured out how to raise his kids with minimal help and get back on the water. He bought a shell of a boat and cajoled friends and neighbors to help finish it to accommodate a wheelchair.

It was one of thousands of lifehacks and engineering iterations that, with a small confederacy of helpers, made living on the island possible. Four decades on, Klarén is tackling carbon with a similar can-do.

The northern reaches of the world are most susceptible to climate change. If Klarén wasn’t literally raised on the North Sea, she might have a different profession.

High school was on the mainland — bike to ferry to bus, 1.5 hours each way. That’s 90 minutes a day to notice the winter getting shorter, the ice getting thinner.

“She was like all teenagers,” Klarén’s brother Markus Bergendahl recalls, “partying and being with friends and just living life. …But I think she started to realize that she needs to do something.”

Her true “aha moment” came in 2006 when she saw Al Gore’s An Inconvenient Truth while studying civil engineering at Chalmers University of Technology. Seeing the global scope of climate damage and the world ignoring the solutions at hand to cut emissions put her on edge.

“There was just this boiling frustration,” she says.

The only antidote, she found, was confronting the problem head-on just as her father had confronted life after his accident. One of her takeaways from Gore’s documentary: Data was a font of hope.

“He put numbers on this; he’s doing graphs,” she said. “I realized if we can pin this down, we can solve it.”

Klarén had sustainability roles for more than a decade at Ikea and KappAhl, a Swedish apparel retailer, before landing at Polestar in 2020.

“I had started obsessing over the company,” she recalls of Polestar. “They were radiating this vision of sustainability, and when I got the call I just thought: ‘This is right; this feels like home.’”

A few weeks before Klarén jetted to Dubai, her father came down with a bad infection and died. He was 71 years old, still building and driving boats, still engineering the life he wanted that was both sustainable and uncompromised.

Klarén thinks of him on Sundays when she goes for a swim (regardless of the weather) and when she indulges one of her few climate vices, a drive in her gas-powered boat.

Niche player for now

Reminding consumers about the sizable stomp of a product’s carbon footprint is a risky strategy. For some, it could be a turnoff akin to sticker shock, particularly for an EV most would consider eco-friendly. It’s also an expensive exercise, which Polestar has stuck with during a fraught financial period.

In the past two years, Polestar shares have swooned more than 80% and in February, Volvo Cars said it would stop funding the company and reduce its stake from 48% to 18% as it focuses on its own EVs.

Barclays analyst Dan Levy, meanwhile, has cast doubts on whether the company can ever grow beyond a niche player. “Although [Polestar] has talked to potential to reach volume in the 300,000 range [similar to Porsche], we believe there will be a show-me component to the upcoming model introductions,” he wrote in a recent report.

Ingenlath, the Polestar CEO, however, considers the company’s meticulous approach to sustainability a competitive advantage. If buying an EV is an exercise in value signaling, it stands to reason that the brand with the strongest such signal will have particular appeal.

The Polestar chief also figures that regulators will eventually require all carmakers to generate life-cycle assessments for each of their machines. Both Europe and California have drawn up carbon disclosure mandates for companies of a certain size. In July, the European Union adopted a new regulation requiring carmakers to measure batteries’ carbon footprint. If that kind of accounting is required at the product level, Ingenlath figures Polestar will be ahead of the game and Klarén will be a key player in helping it get there.

“I really think the industry has not understood what a challenge there will be in the next decade,” he said.

Others joining in

While the Polestar 4 may be Klarén’s crowning achievement to date, her impact appears to be spreading across the industry. In June, startup Fisker published a thorough carbon audit of its first EV. Its Ocean SUV emits the equivalent of 29.5 tons of carbon over its lifetime.

Rivian joined the parade this January with LCA reports for its first two vehicles, the R1T pickup and R1S SUV. Each assessment presents a range of results from 37 tons to 66 tons of carbon over 155,000 miles of driving, depending on how much renewable energy is pumped onto the grid in the coming years.

The methodologies for each of these carbon audits are vastly different. There’s no industry standard, so comparing the results can be a misleading exercise. Still, even without a unified approach, the work is encouraging to Anisa Kamadoli Costa, Rivian’s head of sustainability.

“I feel like [these reports] are table stakes,” Costa says, though not every automaker has put theirs in the pot. Rivian has committed to producing a vehicle with half the carbon footprint of its current products by 2030.

“It’s important that we’re tough on ourselves,” she adds.

Recruiting the big players

Each of these companies, however, is relatively niche. Last year, Polestar delivered 55,000 vehicles, while Rivian shipped 50,000 trucks, outputs that heavyweights like Ford and General Motors match in less than a week. For Klarén, getting major automakers to compile LCAs for their vehicles and publish them is essential to making car carbon footprints a part of every buyers’ decision-making process.

“For it to change, the big players need to step in,” she says. “These companies know every bit of their emissions. …They don’t release them, honestly, because I don’t think anyone’s asked for them.”

General Motors, for example, has “secured” enough renewable energy to power its US facilities, but declined to discuss LCAs. Stellantis, meanwhile, says it compiles LCA reports, but has yet to share them publicly. Ford Motor agreed to discuss LCAs with Bloomberg Green, but only on background, not for attribution.

Klarén’s work could force their hands, according to Matt Novack, senior director and head of climate risk at Riveron, a Dallas-based consultancy.

“As more companies do it and there’s more transparency, it moves the goalposts a bit,” Novack says. “Over time, more and more consumers are paying more attention to it.”

Hyundai, for example, started compiling LCA reports in 2021 and has since completed audits for 20 models. Its cleanest car, the battery-powered GV60 SUV from its Genesis brand, is responsible for 25 tons of greenhouse gas emissions, based on a 155,000-mile life-cycle.

At the same time, suppliers are rushing to clean up their operations, lest they lose business from companies like Polestar. “It just gives them a competitive edge,” Koffler, the technical director at Sphera, says.

Eventually, Koffler thinks a number reflecting a vehicle’s life-cycle emissions will be on every window sticker, right next to the price and other critical specifications.

“I’m an optimist,” he explains, “but I’d like to say it happens sometime in the next five years.”

Klarén’s effort to cut carbon will continue regardless of whether regulations come or not. In fact, it’s getting more ambitious.

She’s turning more attention to Polestar’s moonshot goal to create an entirely climate-neutral vehicle by 2030, notably without the crutch of carbon offsets. The effort is dubbed simply Polestar 0.

Meanwhile, Polestar is launching its fifth model next year, a sporty sedan that will require a whole new factory in China. To get to 0, the company needs to iterate on 5. Klarén wants to be sure it’s her cleanest car yet and is already obsessing over the details.

“Trust me,” she says. “We have a list.”

Read the full article here