Betting against technological progress seems to be in vogue now. That’s been a terrible bet since The Industrial Revolution.

But when it comes to electric vehicles, the pessimism seems unending. Batteries will never get more energy-dense, the proliferation of electric motors will cause a permanent shortage of copper and rare earth minerals, and the planet will run out of lithium before your EV’s third lease payment.

How many papers and opinion columns have you read like that?

If you tune into the technology that’s available even right now, though, you’ll realize those columns are total bullshit. Batteries are about to take a big step, power electronics are striding ahead already, and electric motors are positively rocketing into the future.

In the case of the latter two, we’re talking about components and drive units already in cars, not some YouTube thumbnail pipe-dream. In the case of battery cells, too, the technology already exists. It’s simply on its way to being industrialized.

Let’s get batteries out of the way first, because that seems to be on the front of everybody’s mind. Solid-state batteries are real. Suppliers to major automakers like Ford, BMW, and Volkswagen have already sent them cells for verification. These suppliers didn’t find them on Alibaba, they aren’t some slurry-state middle-ground that’s being hyped to the moon in China. They’re real solid-state cells that are going to end up in cars. BMW is claiming it will have an SSB-powered concept vehicle “before 2025.” After that, it’s just a matter of testing and scaling the technology. BMW is already working on it.

SSBs made by Solid Power, QuantumScape, Factorial Energy, and more all have early cells with energy densities in the range of 400 wh/kg or higher.

These solid-state cells offer far lower internal resistance than their liquid-electrolyte counterparts, which means lower heating under load. Reduced cooling requirements will simplify pack construction considerably, lowering costs. For reference, the Hummer EV’s roughly 3,000-lb battery pack is an absolute monster, but only around 1,730 pounds of it is actually the battery cells. The rest is cooling passages, electronics, and structural components.

At right around 212 kilowatt-hours, it contains a ton of energy, but if it was full of SSBs, it would be an entirely different beast. Multiple solid-state manufacturers report energy densities in the range of 390 watt-hours per kilogram. Replace the conventional lithium-ion cells in the Hummer, and you would get a 306-kWh pack. An increase in energy of nearly one-third, just by swapping cells.

Power electronics are also making big progress. Many inverters currently use insulated gate bipolar transistors, commonly referred to as IGBTs. They work, but the industry already knows that silicon carbide and gallium nitride are the future for electric vehicles large and small. Major automakers have either already adopted Silicon Carbide or are in the process of doing so.

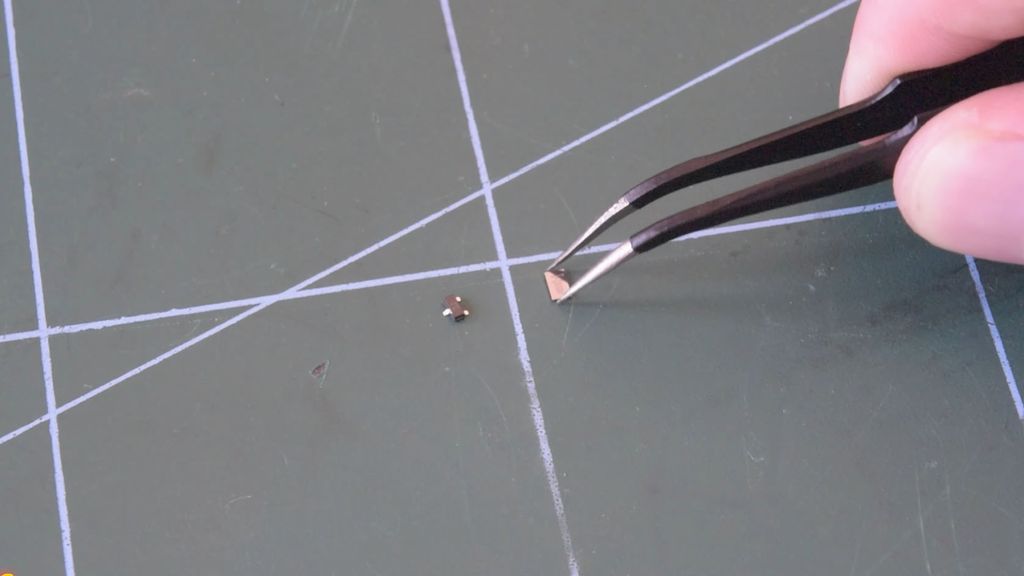

The MOSFET on the right is an HEMT. Despite its size, this unit, made by Nexperia, can switch up to 60 amps at 100 volts.

The switch to Silicon Carbide increases the efficiency of inverters, allowing for greater range. Likewise, while gallium nitride is currently used for lower-power applications like DC-DC converters, (i.e, the devices that take high battery voltage down to 5-12 volts for in-car accessories), they are already being prototyped into full-sized traction inverters, which promises to reduce the size, cost, and complexity of these devices. Power transistors that used to be the size of a quarter are being replaced by more efficient units the size of a grain of rice.

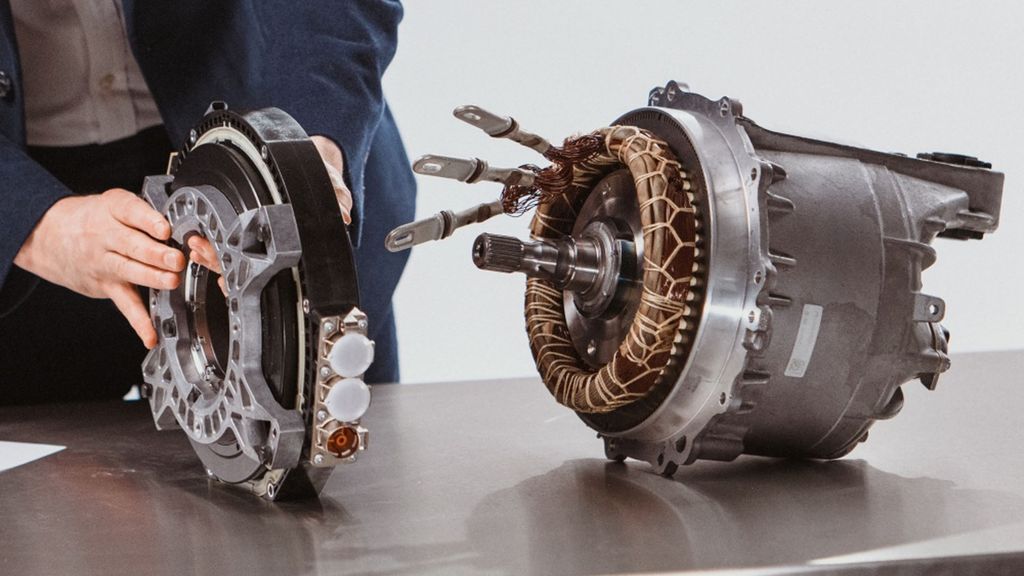

If none of the latter two technological advances are enough, electric motors themselves are simultaneously becoming lighter, smaller, and more powerful. Axial flux motors are already in low-volume production cars from McLaren, Ferrari, Koenigsegg, Mercedes-Benz, Lamborghini, and more. These are real motors capable of providing a passenger car with adequate power despite hilariously low mass. A 300-horsepower car in the near future could be powered by an electric motor that weighs less than your average watermelon. These are motors being developed right now by the industry leader, YASA.

Despite being considerably smaller and lighter, the YASA motor on the left produces similar power to the radial flux it replaces on the right. It’s also not the best motor the company produces.

Drive units will shrink to sizes that are going to seem legitimately funny. Batteries that already exist are offering nearly 400 wh/kg. This newfound energy isn’t just a drop-in, though. It’s set to be used more efficiently than ever. None of these technologies are impossible, they are inevitable. In small volumes, all of these technologies already exist. We must simply wait for mass-market adoption.

Once you learn just a little bit about this stuff, once you get a passing familiarity with MOSFETs, or battery cells, or electric motors, you begin to understand just how amazing the next few years will be. Our current era of EVs will look stone-aged in hindsight. When we’re all commuting in fully electric or hybrid cars featuring these amazing advancements, we’ll have learned once again, never to bet against progress.

Read the full article here