The Cadillac Lyriq is one of the first vehicles to use GM’s Ultium platform. This drivetrain system now underpins all of its current and upcoming electric vehicles, other than the outgoing Chevy Bolt EV. After driving the Lyriq and liking it very much, I was interested in the precise details of the car’s pack and the larger Ultium system. So I interviewed Jerry Beemer, who leads GM’s EV Propulsion team. If you want to know everything about this system down to the individual cells, he’s your guy.

| 2024 Cadillac Lyriq AWD | |

| Battery Chemistry | NMC (3.6V – 3.7V nominal) |

| Cell Form Factor | Pouch |

| Cell Capacity | 103Ah (~371Wh) |

| Total Module Count | 12 |

| Module Configuration (series, parallel) | 8S 3P |

| Pack Configuration | 96S 3P |

| Nominal Pack Voltage | ~345V |

| Calculated Pack Capacity | ~106.79 kWh |

| Official Usable Pack Capacity | 102 kWh |

The Ultium platform currently consists of packs made from the same building blocks. The core of this system is the Ultium battery cell, a long and slender 103 amp-hour (Ah) pouch utilizing a derivative of the nickel manganese cobalt (NMC) chemistry. That means a peak voltage of around 4.2V and a nominal voltage of around 3.6V. The upcoming Chevy Bolt will allegedly be on the same platform but will utilize a lithium-iron-phosphate chemistry. That means the peak cell voltage will be around 3.65V, with nominal coming in around 3.2V.

GM’s 103Ah Ultium battery cells

It’s unclear if these cells will take the same shape as the current Ultium cells, but Beemer told me the cell itself is not vital to the platform. In China, for instance, “We sell Lyriqs with a module-based pack like we have today, but it’s a different chemistry, a different form factor of prismatic cans in those packs” Beemer said.

In other words, key things like the battery management system, module-centric pack construction, and other details, like how power electronics communicate with each other are what make Ultium what it is. The system is not defined by the 103Ah cell that most of GM’s North American EVs use.

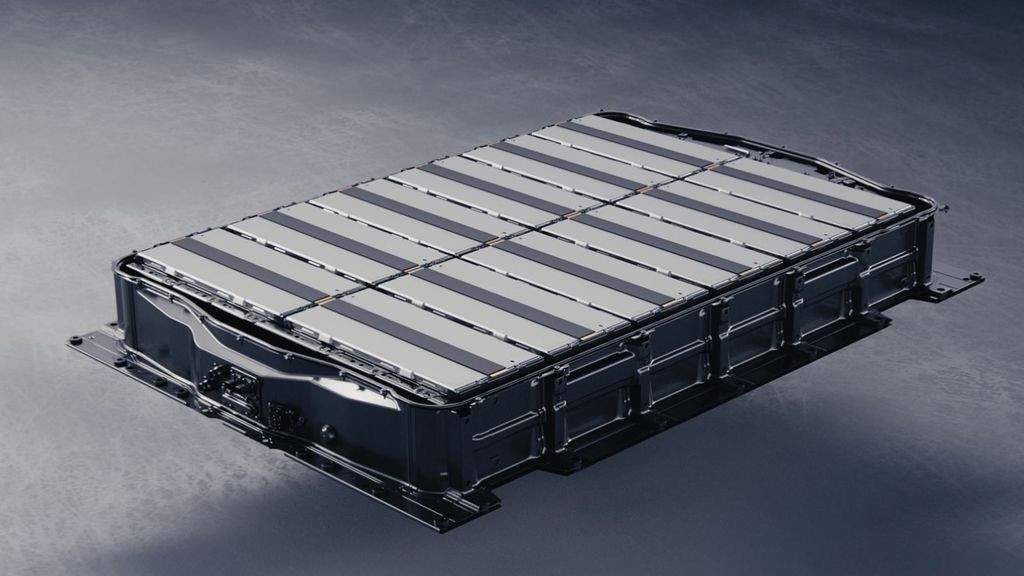

Speaking of these cells, 24 are stuffed into each of the Lyriq’s modules in a 8S 3P configuration, giving a nominal module voltage of roughly 29V. Every module is wired in series to achieve the Lyriq’s 96S pack configuration. This detail belies GM’s confidence in its lower voltage architecture. A rework in module construction would be required to push the voltage higher. Because of this, vehicles carrying fewer modules than the Lyriq will likely operate at a lower voltage.

The Hummer EV utilizes the same cells and modules, however the pack configuration of that monster is 96S 6P—effectively two Lyriq packs stacked on top of each other. The Hummer drives its motors at 400V but can charge at 800V thanks to contactors that wire the pack’s two halves in series, effectively providing a 192S 3P layout.

The Hummer EV’s battery pack

In terms of feeding the drivetrain with that higher voltage, Beemer said the automaker “looked at 800 volts… in the context of full-line manufacturing.”

However, GM doesn’t believe higher drive voltages are a key piece of the puzzle, at least right now. “[I won’t] say that we won’t ever go there,” Beemer told me, but he indicated that driving lower costs by building production volume was a more important first step.

The lower voltage clearly isn’t hurting the system’s discharge rates. The Hummer’s battery, despite operating in the region of 400V, can still provide a burst of 745 kilowatts (1,000 horsepower). The AWD Lyriq with half of the modules can logically provide a peak output of around 373 kW (500 hp).

The Lyriq can charge at 190kW continuously from a station. Calculating a peak charge voltage is difficult because GM is understandably cagey about revealing the Ultium cell’s charge and discharge voltage buffer—other automakers developing battery packs would love to know that kind of thing.

This buffer is the difference between the calculated pack capacity with a known peak voltage, derived from the chemistry, and the stated usable capacity from GM. To be precise, each cell is not getting charged to its max of around 4.2V and is not discharged to its minimum of 2.0V-2.8V mostly for the sake of cycle life and safety. A peak estimate of 4.1V would mean a charging voltage of 393.6V.

In terms of burst charging under regenerative braking, the Lyriq can harvest up to an observed 240 kW, which speaks to the confidence GM has in the system. If it were conservative, we wouldn’t see regenerative braking figures much higher than the pack’s continuous charge rate.

It will be even more interesting to see where the automaker takes these charge/discharge rates in the Lyriq V, which is a widely speculated performance version of the car. It will likely push these charge/discharge limits even higher, perhaps without changing out the core cell.

Indeed, Beemer said the automaker has “not realized the full potential” of the unit yet. In the case of GM, this means working out the physics of what should happen to the cell/module/pack under certain conditions, and correlating that information to test data.

“The vast majority of our work now is analytical and then supported by a few key tests that validate,” Beemer said.

So while GM applies its 103 Ah cell in the 8S 3P module to most of its EVs, testing data may indicate that different configurations are possible. As the automaker gets further into electrification, we can expect more potential to be unlocked from whatever form factor seems ideal, whether it’s pouches, cylindrical cells, or prismatic cans.

An exciting time in the world of electric vehicles.

Read the full article here